BlowerShowa Denki Group |

|

PT Okaya Indonesia sells and supports Showa Denki blower products in Indonesia.

►Application example: For boiler combustion

|

Customer information

Product information

|

Image of use |

|

Background of product adoption Blowers blow air to promote combustion in boilers that use wood chips and pellets as fuel. Since this boiler is used outdoors, the motor of the blower must be equipped with outdoor specifications. Normally, it takes a long time to deliver a commercially available motor, but at Showa Denki, it is a finished blower. |

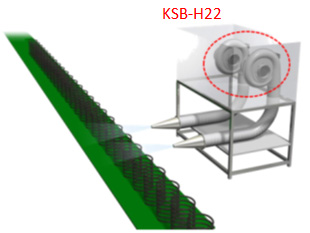

►Application example: to cool the spring after heat treatment

|

Customer information

Product information

|

Image of use |

|

Background of product adoption After the heavy springs of auto parts are heat treated, they require rapid cooling to transfer to the next process. With the installation of a blower, air is blown to the right place using a nozzle to cool the spring, which reduces the total production time. |

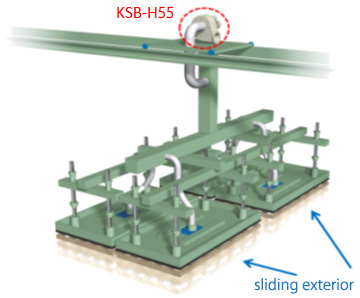

►Application example: For vacuum transportation of building materials

|

Customer information

Product information

|

Image of use |

|

Background of product adoption The customer must haul onto the line for preparation for manufacture and delivery of residential exterior siding (boards, etc.). Since the large-sized sliding has to be transported frequently, a blower with high pressure and high air volume is adopted. By sucking the sliding evenly from the vacuum bearing, the large sliding can be easily transported |

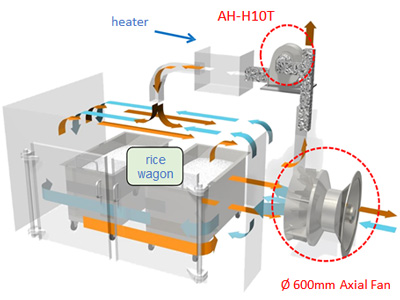

►Application example: to dry rice

|

Customer information

Product information

|

Image of use |

|

Background of product adoption Initially, the customer circulates the inside of the dryer with a standard axial fan to dry the rice, and sends out hot air by heating. |

►Application example: For air seal door to keep out insects

|

Customer information

Product information

|

Image of use |

|

Background of product adoption The customer is a miso producer. When opening and closing the shutter, insects often infiltrate so that it interferes and becomes a problem in terms of hygiene. when we proposed a facility that combines a blower and a slit nozzle, preventing insects from entering. |

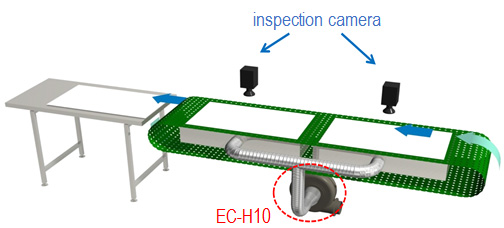

►Application example: For adsorption of printed matter during print inspection

|

Customer information

Product information

|

Image of use |

|

Background of product adoption When inspecting the quality of label prints on sake brewed products with a camera, the printed matter is adsorbed and fixed. Initially, two eddy current fans were used, but by replacing them with the centrifugal EC-H10, cost reduction, energy saving, and space saving can be achieved. It was realized. |

►Application example: For odor recovery of cleaning liquid

|

Customer information

Product information

|

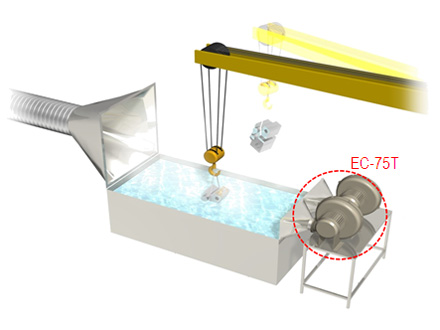

Image of use |

|

Background of product adoption Since the work is transported by a crane and thrown into the washing tank, a hood cannot be installed at the top of the washing tank. Therefore, in the past, it was not possible to exhaust the odor generated from the washing tank. Therefore, we proposed a push-pull type exhaust system and pushed the odor into the hood from the side of the washing tank to solve the customer's problem. |

►Application example: For removing oil adhering to the work

|

Customer information

Product information

|

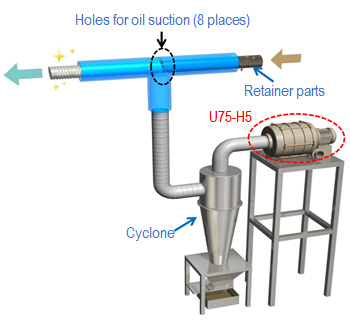

Image of use |

|

Background of product adoption Initially, the oil was drained with an air blow to remove the oil adhering to the retainer parts, but it was shelved due to the heavy scattering of oil. Next, I succeeded in removing the oil using a vacuum cleaner, but as a result of continuous operation, the motor burned out. |

►Application example: For maintaining the function of equipment in a corrosive environment

|

Customer information

Product information

|

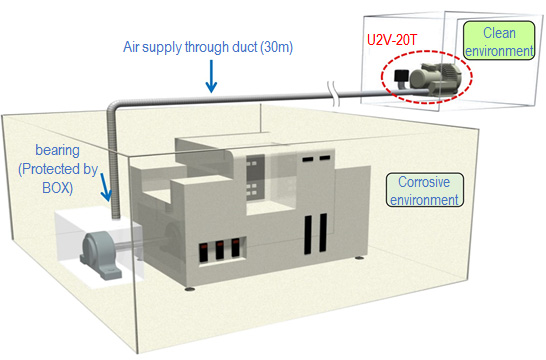

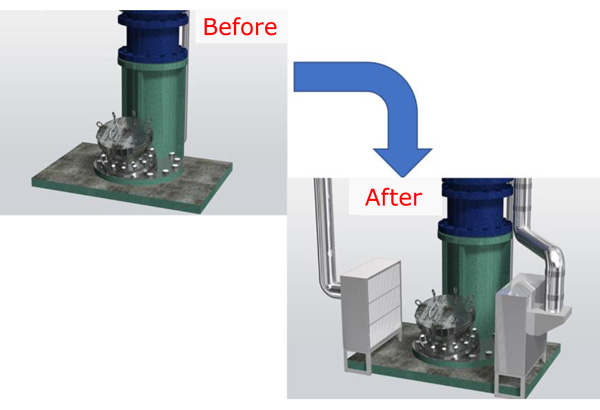

Image of use |

|

Background of product adoption Gases that easily corrode metals are widespread in our customers' factories. Since this corrosive gas shortens the life of the bearing, the bearing was initially surrounded by a BOX and a compressor was used to supply fresh air to the inside. However, because continuous air supply was required, the amount of air in the compressor was insufficient. Therefore, when the high-pressure vortex fan U2V-20T was proposed, it was decided to be adopted after clearing both the amount of air and the distance (about 30 m to the air supply destination). |

►Application example: For transporting plastic plates

|

Customer information

Product information

|

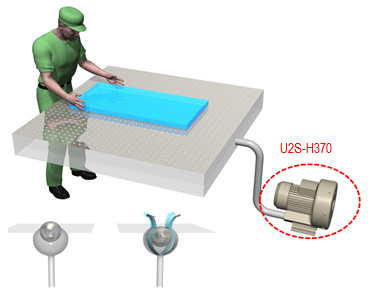

Image of use |

|

Background of product adoption In order to cut the plastic plate material, the plate material is manually transported to the blade part of the processing machine. At that time, a transport line combining a high-pressure eddy fan U2S-370 and an air transport table (diameter of about 3 mm) is used so that the plate material can be smoothly transported. With this combination, the amount of air required for transportation was small, and a compact blower could be used. |

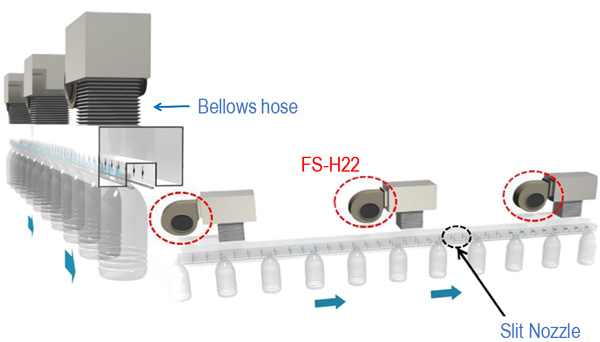

►Application example: For drying paint booths

|

Customer information

Product information

|

Image of use |

|

Background of product adoption The work passes through the paint application area and is put into the drying furnace by a suspension conveyor. The customer's problem was that the hot air in the furnace leaked from the inlet and outlet of the drying furnace. Due to the leakage of hot air, the temperature inside the furnace was uneven and the temperature at the work site was rising. Therefore, we applied an air curtain using a slit nozzle at the entrance and exit, and succeeded in eliminating hot air leakage. |

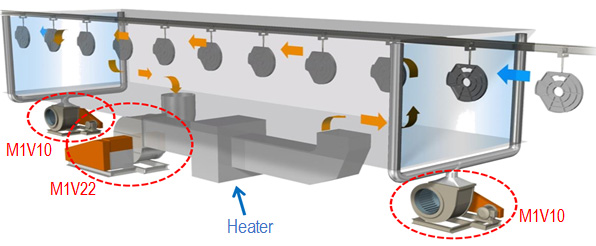

►Application example: For transporting PET bottles

|

Customer information

Product information

|

Image of use |

|

Background of product adoption A blower is used to transport the empty PET bottles to the beverage filling machine. |

►Application example: For local exhaust of organic solvents

|

Customer information

Product information

|

Image of use |

|

Background of product adoption After receiving instructions from the Labor Standards Inspection Office, we conducted work environment measurements, but the results were poor and we were at a loss as to what to do. He suggested including an enclosed hood and ducting, with a fan to exhaust the air. After installation, work environment measurement was also placed in the first management category, and the Labor Standards Inspection Office judged that there were no problems. |

►Application example: Exhaust of gravure printing process

|

Customer information

Product information

|

Image of use |

|

Background of product adoption A downward-suction local exhaust system was installed to exhaust organic solvent vapors. However, the work environment measurement results were poor, so we reexamined the enclosure type hood. The work environment measurement was also judged to be the first management category and the Labor Standards Inspection Office judged that there was no problem. |

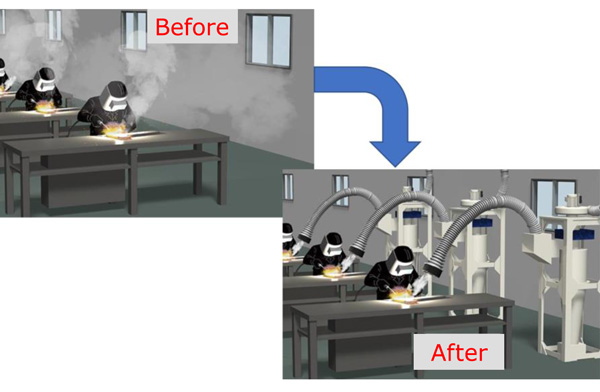

►Application example: Welding fume dust removal exhaust

|

Customer information

Product information

|

Image of use |

|

Background of product adoption The maintenance of the dust collector for the fume generated in the welding work is difficult, and even if the air is exhausted with a blower, the dust is scattered outside, so I was at a loss as to how to collect and exhaust the dust. By combining a fume exhaust fan and a cyclone, it is possible to prevent welding fumes and dust from scattering to the outside. |

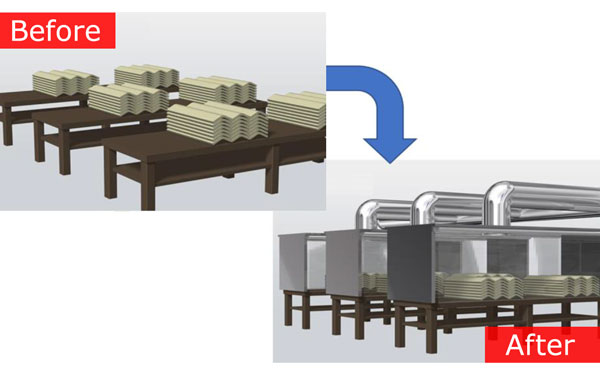

►Application example: Measures against exposure to specified chemical substances

|

Customer information

Product information

|

Image of use |

|

Background of product adoption I was at a loss as to what kind of exhaust equipment to introduce because the scope of work in the process of introducing chemical substances is wide. By introducing a push-pull ventilation system, it was possible to prevent workers from being exposed and to contain the source. |

|

For further information and inquiries, Deltamas office: +62 21 2909 3861 |