Collaborative RobotJAKA |

|

PT. Okaya Indonesia is distributor JAKA Indonesia market. PT. Okaya Indonesia sell and support of JAKA Collaborative Robot in Indonesia.

JAKA COBOTS |

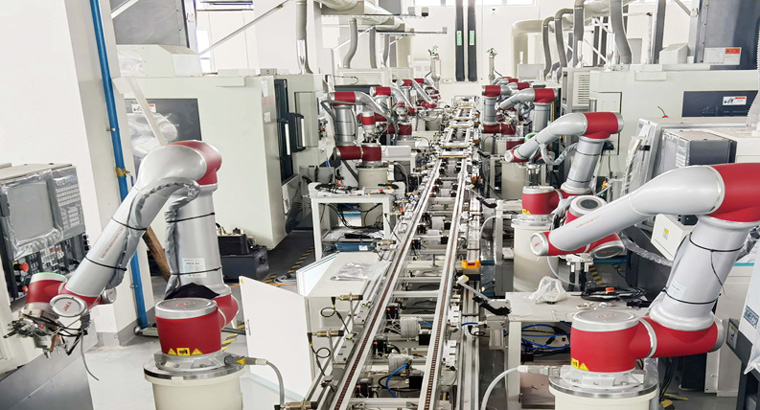

At present JAKA has launched several series of cobots: JAKA Zu ® series (general version, force control S version), JAKA All - in - one series, JAKA Lens series. These versatility and flexible characteristics can be easily used in industrial, commercial, services and other fields to meet the demand of various application scenarios.

With the achievements in drive control integration, integrated joints, drag programming, wireless interconnection and other aspects, JAKA series have been successfully applied in several industrial automatic production fields, which is providing a continuous and strong equipment foundation for industrial innovation.

JAKA Zu® Series Cobots |

|

JAKA Zu® 3 Cobot

► Product Features ●Lighter self-weight : Self-weight 12kg, payload 3kg, working radius up to 626mm. ► Recommended Markets 3C electronics, Medical treatments, Scientific researches, Injection molding

|

|

JAKA Zu® 5 Cobot

► Product Features ●Compact and portable : Self-weight 23kg, payload 5kg, working radius up to 954mm. ► Recommended Markets Metal processing, 3C electronics, Chemical industry

|

|

JAKA Zu® 7 Cobot

► Product Features ●Heavier payload : Self-weight 22kg, payload 7kg, working radius up to 819mm. ► Recommended Markets 3C electronics, Medical treatments, Automotive industry, Chemical industry

|

|

JAKA Zu® 12 Cobot

► Product Features ●Heavier payload : Self-weight 41kg, 12kg payload, working radius up to 1327mm. ► Recommended Markets Metal processing, Automotive industry, Injection molding, Pharmaceutical

|

|

JAKA Zu® 18 Cobot

► Product Features ●Heavy payload : Self-weight 35kg, 18kg payload, working radius up to 1073mm. ► Recommended Markets Metal processing, Automotive,Injection molding, Medical equipment

|

|

Traditional industrial robot production lines are repetitive, boring, mechanically operated and full of potential industrial injury risk. Enterprises also face the problems of constantly increased labor costs and compressed enterprise ROI (return on investment). |

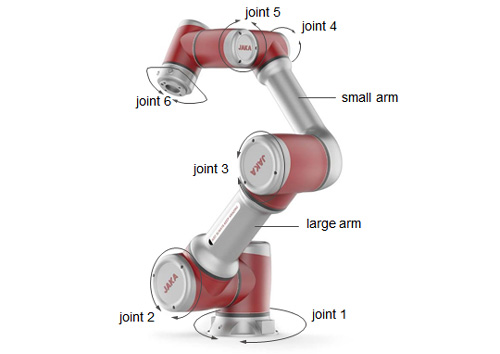

JAKA Zu® Structure and Control Cabinet |

JAKA Zu® Structure

|

Control Cabinet

|

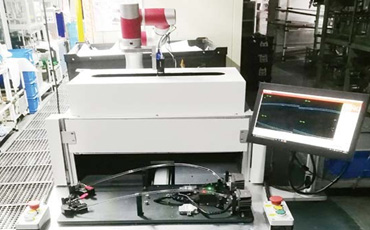

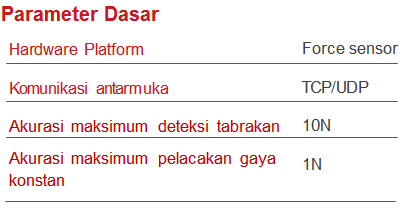

S version of JAKA Zu® Cobots |

|

► Installation method Mount at end or base |

|

|

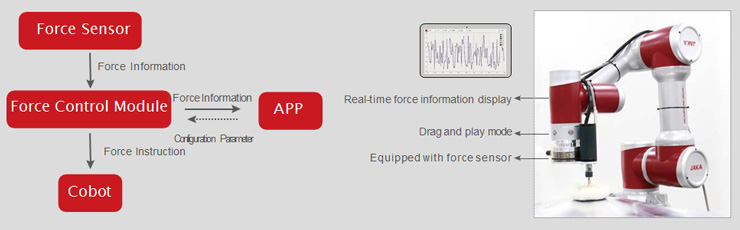

► Product Features JAKA Zu S-series cobots APP software are equipped with force control module, which can be directly set the safe force value and automatically identify payload. Real time displaying force value convenient different application requirements of setting up control parameters. And the constant force or speed mode can be selected in JAKA App. |

|

► Product Description S version of JAKA Zu cobots equipped with advanced industrial force sensor, and integrated with force control algorithm of independent intellectual property rights, improve the perception of cobots and provide better human-COBOT interaction experience and security guarantee for customers. They provide a variety of force control solutions such as constant force, normal tracking and speed mode to realize full-arm collision detection.

|

|

|

► Product Features ●Display the force number on APP in real time ●Safe contact force and force control parameters set on APP ●Constant force control and normal tracking ●Full arm collision detection |

|

Function Diagram

JAKA All-in-one Cobots |

|

► Product Description JAKA All-in-one Cobots innovatively adopt the product design principles of JAKA S³ (Smart, Simple, Small), and integrate with advanced robot technologies such as wireless teaching, graphical programming, and visual safety protection. These technologies revolutionize the way of Human-Cobot interac- tion, improve the safety of human-robot cooperation and greatly reduce the threshold of robots usage. Meanwhile, JAKA All-in-one Cobots deeply integrate vision function to ensure the natural interaction and autonomous adaptation among cobot, human and operating environment, that signifi- cantly broadens the robot application boundary. |

|

|

► Product Innovation ● Smart-Intelligent learning : ● Simple-Human-COBOT cooperation : ● Small-High integration : |

JAKA Lens Series |

JAKA Lens 2D► Product Description JAKA Lens 2D integrated with high-resolution 2D camera, equipped with specialized light source module and optional camera Lens, provides users with comprehensive functions and experience of 2D vision. Professional industrial design makes it compact and portable, and exquisite in appear- ance. 2D vision function can be realized by external fixed installation and installed at the end of the mechanical arm. |

|

|

► Product Function ● JAKA Lens 2D inserted in camera, Lens and light source three modules can acquire real-time 2D images, and independent selection of light source on and off. ● Cooperated with the camera communication module and the internal power supply module, the internal power supply and the camera communication can be realized through a single composite cable. Equipped with JAKA 2D vision software, it can be configured through the web interface of the controller. ● With the function of target recognition, visual positioning, camera management, eye-hand calibration, it can realize the rapid configuration and management of 2D vision. |

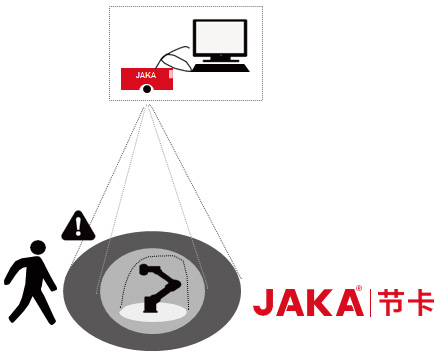

JAKA visual protection system► Product Description JAKA visual protection system adopts industrial-grade wide-angle camera and configures JAKA own independent intellectual property rights of image processing system, connecting with cobot controller. The camera placed above the working area of the cobot monitors the working scenario. When foreign object (people or device) breaks into the monitoring area, the system processes and makes a judge- ment based on the received image, and then sends instructions to the cobot to take corresponding measures to ensure human and machine safety. This product can also be used as a monitoring device to display real-time monitoring working scenes through the interface. |

|

|

► Product Function ● The software interface monitors the protected area in real time and alarms the intrusion of foreign objects. ● The scope and protection type of monitoring area can be user defined. ● Emergency measures can be set on software.

|

Sketch map of visual protection system |

Recommend Markets |

Automobile and accessories, 3C Electronics, Precision manufacturing, Medical devices, Electric appliances, New energy,

Chemical & synthetic fibers, Food packaging, Education, New business, etc.

Automobile and AccessoriesAutomobile and spare parts are industries with high automation level, but due to the complex assembly process and flexible procedures, traditional robots are not applicable to these. JAKA Cobots with the characters of safety and flexibility and interactions cooperation, can not only deal with complicated processes, but also improve the overall factory production efficiency. ► Industry Application |

3C ElectronicsDue to the increase of labor costs and rapid product updates in 3C electronics industry, enterprises are looking for the most cost-effective solutions. JAKA Cobots are compatible, light, suitable for flexible production mode, and can be easily deployed on the production line. Nowadays, JAKA Cobots have an extensive application scope and application prospect in 3C electronics industry. ► Industry Application |

Precision ManufacturingPrecision manufacturing is a relatively labor-intensive and technology-intensive industry. Processes such as polishing, loading and unloading and assembly need an automation solution. JAKA Cobots, compatible and light, are suitable for flexible production mode, and can be applied in production line with high labor intensity, harsh environment and high requirement of operation skills. ► Industry Application |

New BusinessCompanies are looking for solutions to cut costs. Those low-skilled, repetitive jobs are being replaced by more efficient, lower-cost robots. JAKA Cobots cooperated with people can bring novel service experience, which is deeply welcomed among enterprises and young people. Now as a waiter, JAKA Cobots have already been widely applied in cafes, restaurants and supermarkets. ► Industry Application |

More Application Cases |

|

For further information and inquiries, Deltamas office: +62 21 2909 3861 |